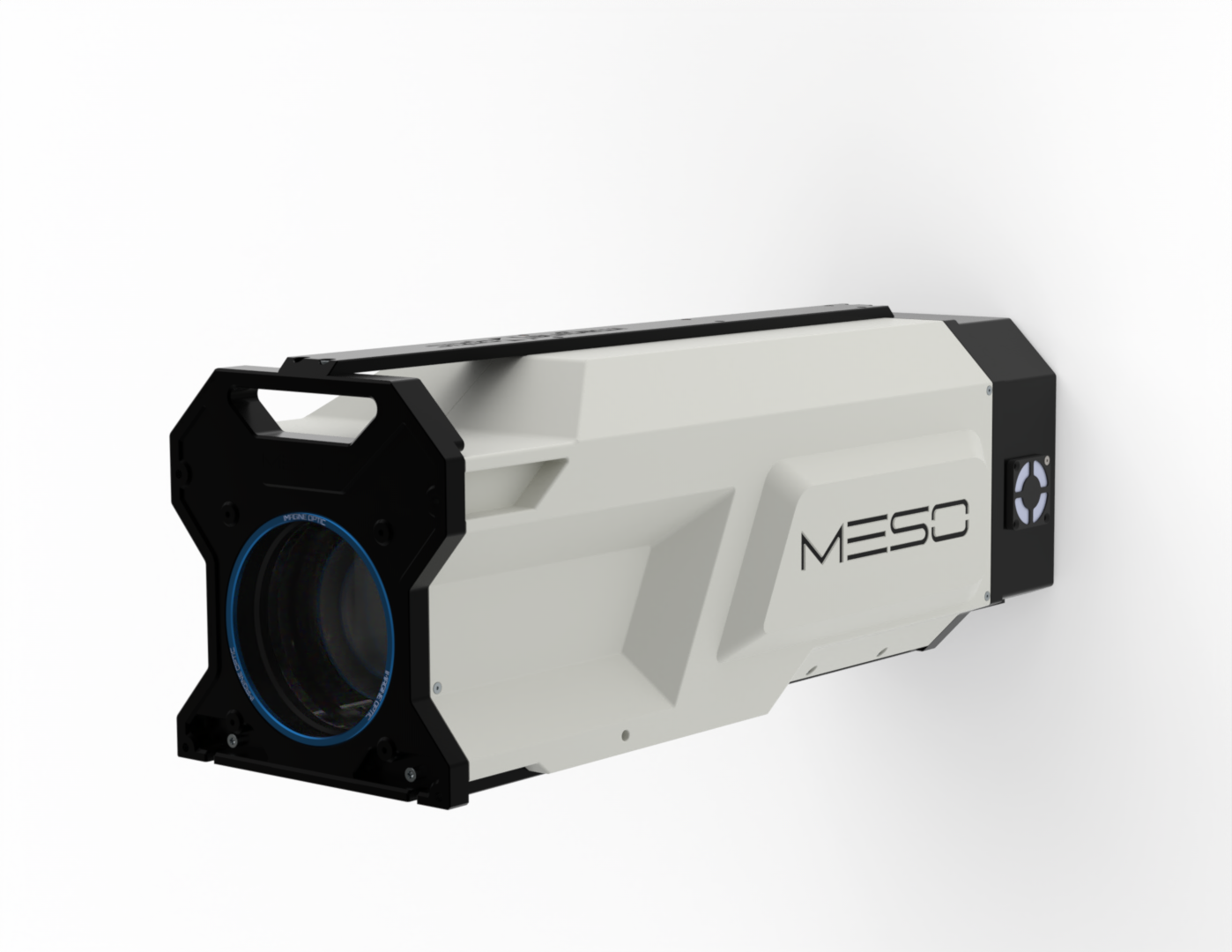

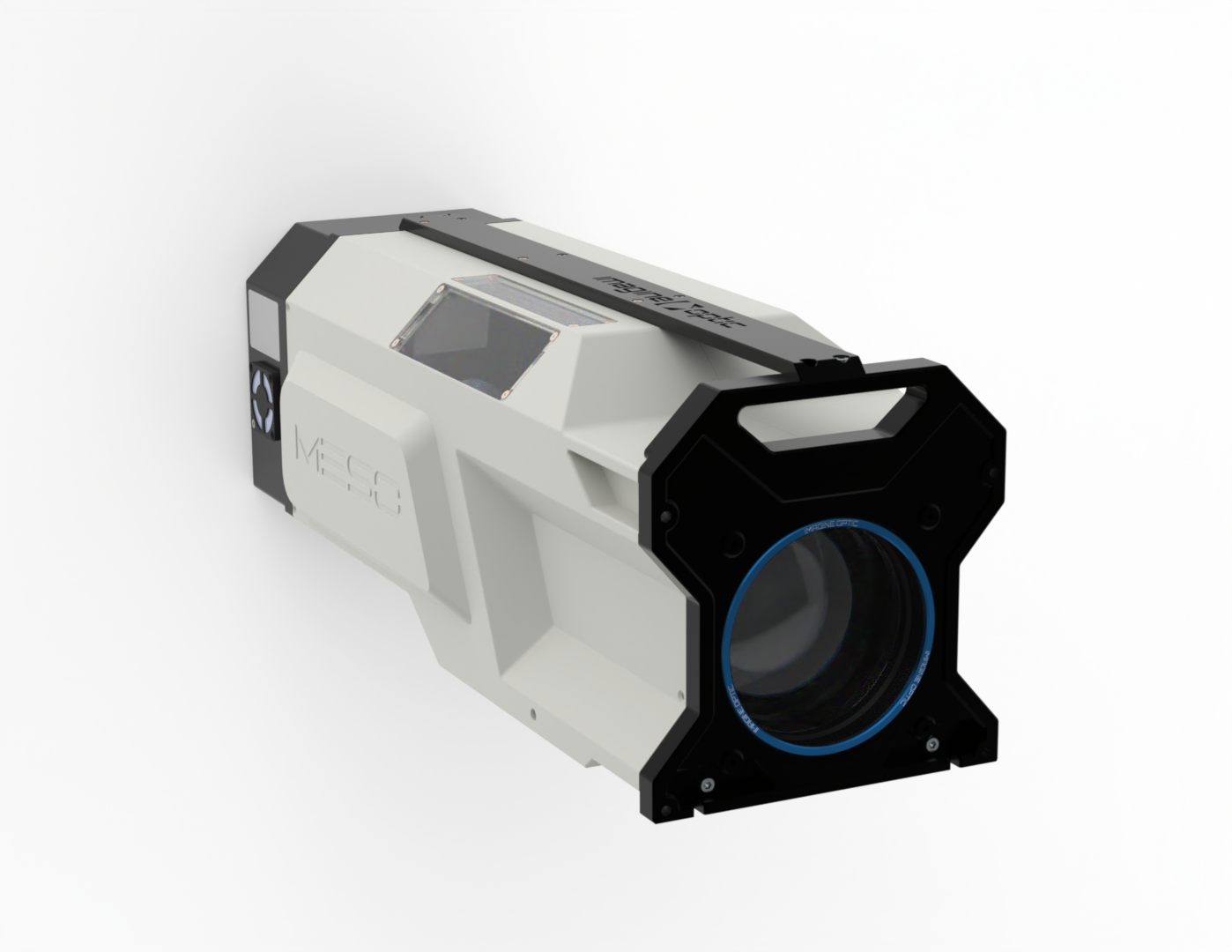

MESO Metrology System

Interferometry Applications

The MESO™ instrument is a metrology solution for easy at-wavelength testing of flat surfaces in any environments. Testing diameter is ranging from 1,5’’ to 6’ in VIS NIR.

MESO Metrology Solution

MESO metrology system is a one-stop solution to many challenges in optical metrology. Shop floor measurements ensure quality control testing and in situ process control of your flat optics right next to the manufacturing line. A unique instrument allows to measure at several different wavelengths with no chromatic abberations and to characterize the whole range of your optics with no loss of resolution.

MESO™ is packed with innovation:

+ LIFT-enhanced high wavefront sensing resolution

+ POP patented procedure for the testing of (thin) plane parallel optics

+ Spot Tracker™ proprietary technology provides absolute measurement of tilt and wavefront.

KEY FEATURES

+ Insensitive to vibrations

+ At-design wavelength testing

+ Insensitive to reflections from sample back surface

APPLICATIONS

MESO is the perfect testing tool for the control of:

| + Parallel Optics + Screens + Filters, dichroics + Mirrors + Beamsplitters + Windows + Substrates + Corner cubes + Crystals |

+ Rods, Disks + Glass wafers + Displays + Machined surfaces + Windshields + Prisms + Large lenses + Optical systems + Beam expanders |

KEY SPECS of MESO metrology system

| + Horizontal or vertical integration + Optical zoom from 1,5’’ (38,1mm) up to 6’’ (152mm) + Testing wavelength from 405 nm to 820 nm + 680 x 500 phase points resolution + 27us minimum acquisition time |

+ Touchscreen interface control + Scripted testing procedures guide the user through all the steps + Automated control of up to 4 embedded wavelengths + Automated control of test diameter + Complete automated test report + ISO10110 standard compliance + Multiformat data export |

WAVESURF supportive Software for MESO metrology system

Wavesurf allows operators and engineers in manufacturing environments to perform wavefront and surface characterization of flat optics and large lenses with just a few clicks. Scripted testing procedures guide users through all the steps. It makes control easy, automated and error-proof.

Description |

Specifications |

| Test Beam Diameter | Optical zoom from 1.5″ (38.1mm) up to 6″ (152 mm) |

| Optical Axis | 4.25″ (108 mm) |

| Dimensions | 63 x 30 x 45 cm |

| Calibrated Range | 405 nm to 830 nm |

| Phase Point Resolution | 680 x 500 |

| Wavelength | Custom 405, 488, 520, 635, 785, 830 nm |

| Interface | USB 3.0 |