Interferometry applications

Home / Applications / Interferometry applications

MESO Metrology System for Interferometry applications

MESO instrument is an extremely robust metrology solution for easy at-wavelength testing of flat surfaces in any environments.

Its insensitivity to vibrations makes it the ideal tool for shop floor measurements close to the production line.

Test your flat optics, mirrors, filters and dichroics of diameters from 1.5’’ up to 6’’ at full LIFT resolution and at any wavelength in the VIS with the same instrument.

Take advantage of our innovative proprietary method to characterize (thin) plane parallel optics and obtain surface shape (RWE) of both surfaces and transmitted wavefront (TWE) with no preparation of the samples

What is interferometry?

‘Interferometry’ is a measurement method using the phenomenon of interference of waves, such as radio, sound or in our case of interest, light.

The working principle of the technology consists on a splitting of the light into two beams that travel different optical paths (distance travelled) and are then combined to produce an interference pattern. As the wavelength of the visible light is short, the fringes of the interference pattern reveal small changes in the differences in the optical paths between the two beams. This is why interferometry has been widely used in optical metrology.

Applications of interferometry in optical metrology

Laser interferometers, such as Fizeau or Twyman-Green interferometers can be used for the measurement of transmitted wavefront, form & flatness, radius of curvature, wedge and prism angle for example.

Wavefront sensing vs Interferometry

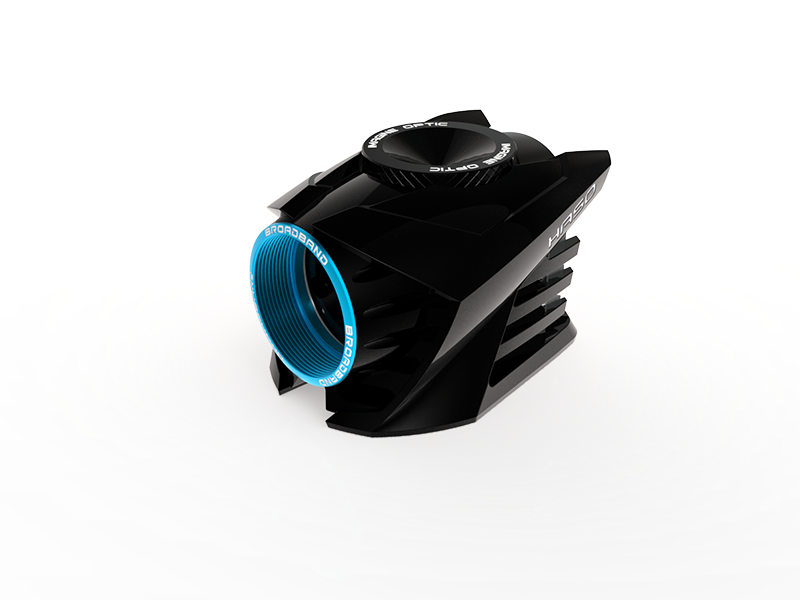

Wavefront sensors, and in particular the wavefront sensors integrated in Imagine Optic metrology solutions -the Optical Engineer Companion (OEC) or MESO-, provide the same kind of information as laser interferometers.

Modern wavefront sensors bring high resolution.

Shack Hartmann-based wavefront sensors commonly implement more than 100×100 microlenses, ie phase sampling points in this case. Each of them samples the incoming beam and focalizes a centroid on a 2D sensor like a camera. By analyzing the position of these centroids, local slopes can be reconstructed.

LIFT me up! In presence of aberrations, centroids not only move laterally on the camera but also change -slightly- their shape. LIFT reconstruction algorithm precisely takes advantage of the intensity distribution of the centroids to reconstruct complex phase at the microlens level, allowing to increase resolution by a factor of 16 times (!) to reach 680×500 phase points.

High-end wavefront sensors can work at any wavelength.

Imagine Optic wavefront sensors can perform metrology at the design or operating wavelength of the sample of interest, as they are achromatic on the spectral range of the cameras embedded, and are not limited to coherent laser wavelengths.

Wavefront sensors are insensitive to vibrations

A wavefront sensor measurement consists in the acquisition of an image by a camera, therefore in the order of 10s of us, on the contrary of a Fizeau Phase Shifting interferometer for example, where a reference surface has to be moved to reconstruct one phase map. Therefore, the wavefront sensor ‘freezes’ vibrations or atmospheric turbulences, making them a perfect solution for easy to implement shop floor measurement and in process control.

Check out MESO white papers and contact us to arrange a test on your optical components.